TECHNOLOGY & RESEARCH - No Polymers. No Microplastics.

Built Without the Baggage

PED coatings were engineered from the start to solve real problems—without creating new ones.

While most controlled-release and binder technologies rely on synthetic polymers, plastic shells, or petroleum-based carriers, PED delivers protection and timing with:

✅ zero microplastics

✅ zero synthetic residues

✅ zero regulatory baggage

Plastic-free by design. Not retrofit.

The Industry’s Dirty Secret: Plastic Coatings

CRFs, polymer-coated seeds, and synthetic spray stickers all have one thing in common: They leave plastic behind. Most are made with:

Polyethylene

Polyacrylate

Polyurethane

Formaldehyde cross-linkers

Oil-based binders

These materials don’t fully degrade in soil and are increasingly under scrutiny for contributing to agricultural microplastics.

The Regulatory Shift Is Already Here

| Region | Change |

|---|---|

| European Union | Ban on non-biodegradable polymer coatings by 2028 |

| California | Restrictions tightening on synthetic inputs and residues |

| Global Brands | Pressure from buyers for plastic-free supply chains |

PED coatings are already compliant—because they were built to be.

What We Use Instead

PED coatings are:

- Bio-based

- Cold-applied

- Inert to nutrient/microbial chemistry

- Soil-degradable via microbial activity

- Free from polyethylene, polyurethane, acrylics, or silicones

No plastic polymers. No plasticizers. No “bioplastic” greenwashing. Just real coatings built to degrade clean.

Microplastic-Free Across All Inputs

One platform. Four real-world use cases:

| Input Type | PED Platform Microplastic Status |

|---|---|

| Fertilizer | ✅ 100% microplastic-free coating |

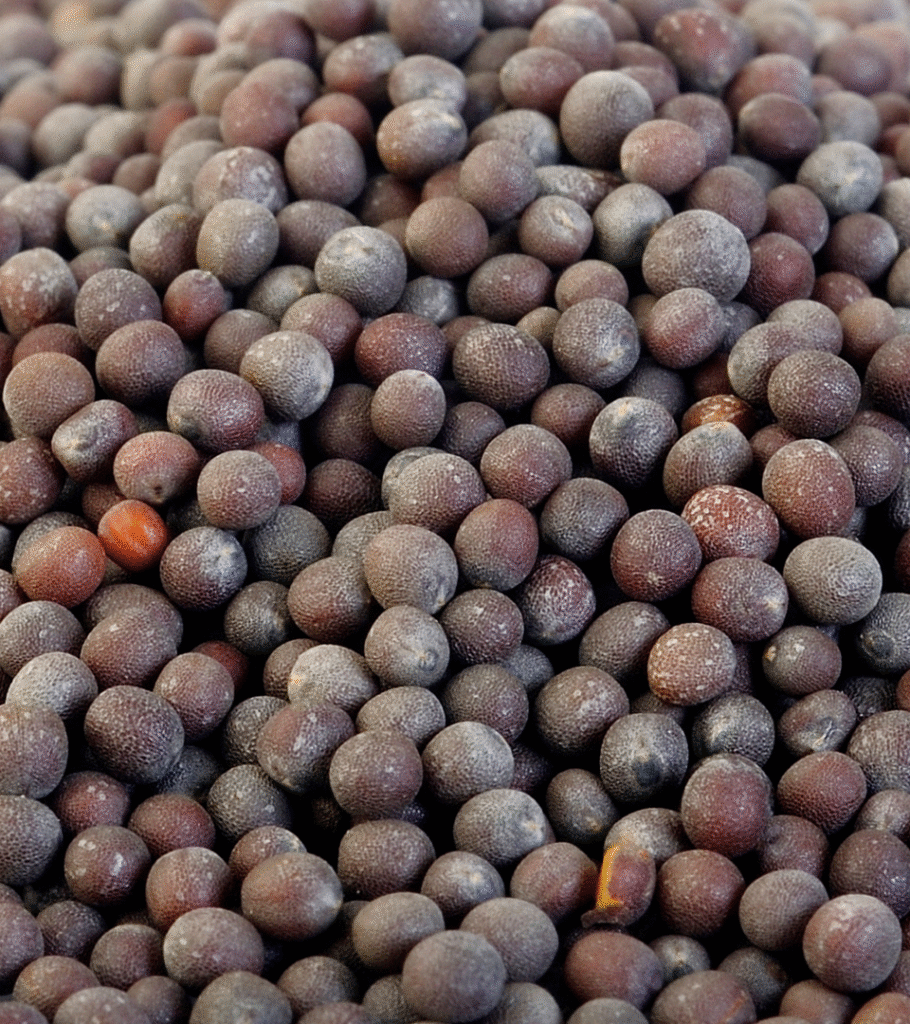

| Seed | ✅ Organic-compliant, no polymer use |

| Biologicals | ✅ Inert and degradable, no coating residue |

| Pesticides | ✅ Dry-applied, zero synthetic carriers |

Why It Matters

Cleaner compliance for organic and regenerative programs. Future-proofed products for global markets. Better alignment with food safety and ESG targets. No unintended soil accumulation or long-term buildup. No tradeoff between performance and responsibility